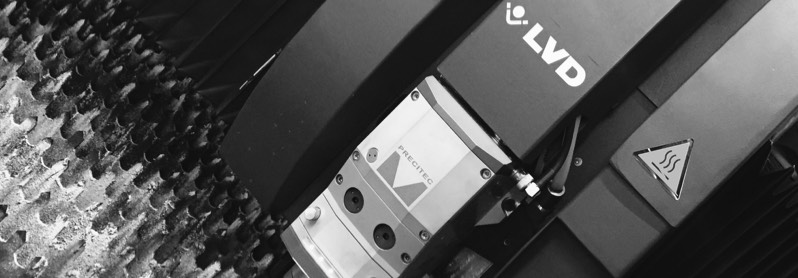

New 4Kw LVD Electra Fiber Laser Installed May 2015

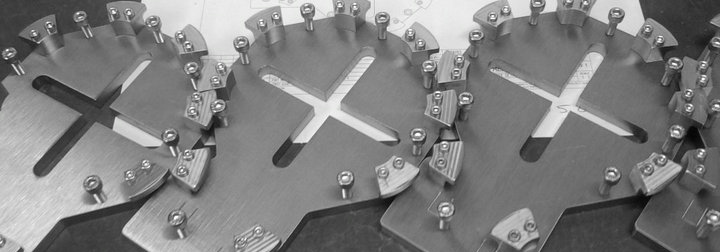

Having gathered considerable knowledge of laser cutting in the past 14 years, our skilled technicians are able to cut many different types of materials, which are avoided by most companies.Speed of cut and the ability to etch, puts the laser ahead of other cutting methods and using our high pressure nitrogen vessel, gives tarnish free superior edge quality.

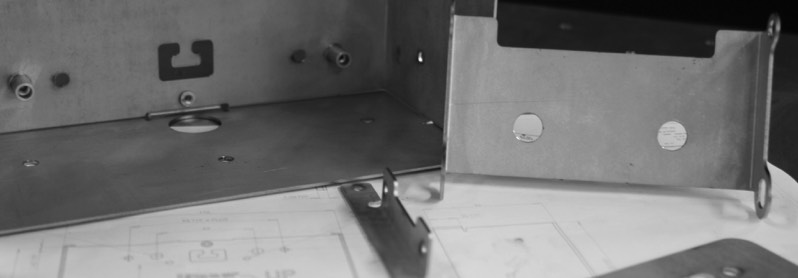

LVD'S multi axis press brake with Laser EasyForm angle measuring,integrated with touch screen operators panel, ensures accuracy through multiple folds. This complete with CADMAN offline programming gives the repeatable accuracy sheet metal designers demand.

Sheet Metal/Fabrication Capabilities

Laser Profiling 3000mm x 1500mm

CNC Multi Axis Pressbraking

CNC Plate Rolling

Radan Programming Suite

NC Pemserting

NC Tube Bending

Welding Capabilities Coded When Required

Mig

Tig

Seam Welding

Spot Welding

Stud Welding

Helium Vacuum Testing

Whenever you find yourself on the side of the majority, it is time to pause and reflect.

Mark Twain

A.W.Clarke Engineering Limited - Sandford Road - Littlemore - Oxford - OX4 4PU - UNITED KINGDOM

Tel: +44(0)1865 777190 Fax: +44(0)1865 711600

E-mail: "ObscureMyEmail"